As a supplier of Hot Glue Envelope Seals, I've received numerous inquiries from customers regarding the potential impact of sunlight on these seals. This question is not only practical but also crucial for businesses and individuals who rely on our products to ensure the security and integrity of their envelopes. In this blog, I'll delve into the scientific aspects of how sunlight can affect hot glue envelope seals and provide insights based on our extensive experience in the industry.

Understanding Hot Glue Envelope Seals

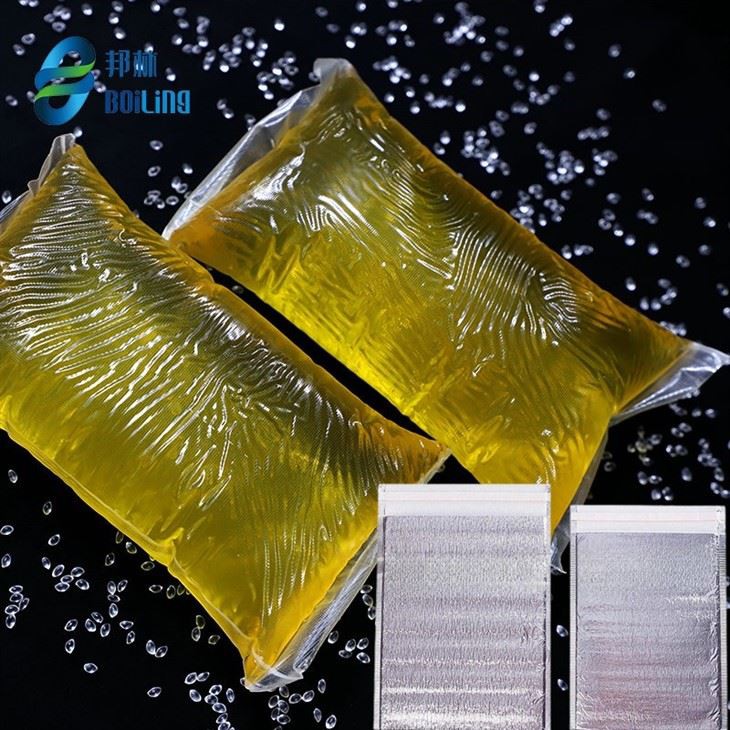

Before we discuss the effects of sunlight, it's important to understand what hot glue envelope seals are. These seals are typically made from a type of adhesive that is activated by heat. When applied to the envelope, the glue cools and solidifies, creating a strong bond that keeps the envelope closed. There are different types of hot glue used for envelope sealing, each with its own unique properties and characteristics.

One common type is Pressure Sensitive Hot Melt Glue For Envelope Sealing. This glue is designed to adhere quickly and firmly to the envelope surface with minimal pressure. It's often used in high - volume mailing operations due to its efficiency. Another type is Low Melt Glue, which requires less heat to melt and is suitable for applications where lower temperatures are preferred. Pressure Adhesive Glue is also widely used, offering a strong bond through pressure application.

The Science of Sunlight and Its Effects on Hot Glue

Sunlight is composed of different wavelengths of electromagnetic radiation, including ultraviolet (UV) light, visible light, and infrared (IR) light. Each of these components can have a distinct impact on hot glue envelope seals.

Ultraviolet (UV) Light

UV light is known for its ability to break down chemical bonds in materials. When hot glue is exposed to UV light, the polymers in the glue can start to degrade. Polymers are long - chain molecules that give the glue its adhesive properties. As the polymers break down, the glue may lose its strength and flexibility. This can lead to the seal becoming brittle over time, which increases the risk of it cracking or peeling off the envelope. In addition, UV - induced degradation can cause the glue to change color, which may not be aesthetically pleasing for some applications.

Visible Light

Visible light generally has less of a direct impact on hot glue compared to UV light. However, prolonged exposure to intense visible light can still cause some degree of heating. If the hot glue gets too warm, it may become softer and less effective at maintaining a tight seal. This is especially true in hot climates where sunlight can be very intense.

Infrared (IR) Light

IR light is associated with heat. When hot glue absorbs IR light, it can heat up rapidly. Excessive heating can cause the glue to melt or flow, which can compromise the integrity of the seal. If the glue melts and then re - solidifies, it may not form a uniform bond, leading to weak spots in the seal.

Factors Affecting the Impact of Sunlight on Hot Glue Envelope Seals

The degree to which sunlight affects hot glue envelope seals can vary depending on several factors:

Duration of Exposure

The longer the hot glue is exposed to sunlight, the greater the chance of damage. For example, envelopes that are left outside in direct sunlight for days or weeks are more likely to experience significant degradation compared to those that are only exposed for a short period.

Intensity of Sunlight

The intensity of sunlight varies depending on the time of day, season, and geographical location. In regions closer to the equator, sunlight is generally more intense, which means that hot glue seals are more likely to be affected. Similarly, sunlight is stronger during the summer months and at mid - day.

Type of Hot Glue

Different types of hot glue have different levels of resistance to sunlight. Some glues are formulated with UV stabilizers, which can help protect the polymers from degradation. These glues are more suitable for applications where the envelopes may be exposed to sunlight.

Testing and Quality Assurance

At our company, we conduct rigorous testing to ensure the quality and durability of our hot glue envelope seals. We expose samples of our glue to simulated sunlight conditions in a laboratory setting. This allows us to measure the changes in the glue's properties over time, such as its adhesive strength, flexibility, and color.

We also test our products in real - world scenarios. We send out envelopes with our seals to various locations around the world and monitor how they perform under different sunlight conditions. This helps us to identify any potential issues and make improvements to our products.

Mitigating the Effects of Sunlight

If you're concerned about the impact of sunlight on your hot glue envelope seals, there are several steps you can take:

Storage

Store envelopes in a cool, dark place. This will minimize their exposure to sunlight and reduce the risk of degradation. If possible, use storage containers that block UV light.

Packaging

Consider using envelopes with UV - resistant coatings. These coatings can help to protect the hot glue seal from UV light. Additionally, using opaque envelopes can reduce the amount of visible and IR light that reaches the seal.

Choosing the Right Glue

Select a hot glue that is specifically formulated to be resistant to sunlight. Our Pressure Sensitive Hot Melt Glue For Envelope Sealing and other products are available in versions with enhanced UV resistance.

Conclusion

In conclusion, sunlight can have a significant impact on hot glue envelope seals. The UV, visible, and IR components of sunlight can cause the glue to degrade, lose its strength, and become less effective at sealing envelopes. However, by understanding the science behind these effects and taking appropriate measures, such as proper storage, using the right type of envelope, and choosing sunlight - resistant glue, you can minimize the risk of damage to your seals.

As a supplier of high - quality hot glue envelope seals, we are committed to providing our customers with products that meet the highest standards of performance and durability. If you have any questions about our products or need advice on how to protect your envelopes from sunlight, please don't hesitate to contact us. We are here to help you find the best solutions for your envelope sealing needs. Whether you're a small business owner or a large - scale mailing operation, we can work with you to ensure that your envelopes are securely sealed, even in the face of sunlight exposure.

References

- ASTM International. "Standard Test Methods for Evaluating the Adhesive Properties of Pressure - Sensitive Tapes." ASTM D3330/D3330M - 20.

- European Adhesive Tape Association. "Guidelines for the Testing and Evaluation of Adhesive Products." 2022.

- Polymer Science and Technology textbooks, various editions.